Alfa Test is providing a full range of test solution from data preparation to full turnkey solution and the complete project management needed for complex applications.

.

We are offering:

- Flying Probe Test – test programs development for analog tests, vectorless tests, power on test / functional test and optical inspections for the complete range of Takaya flying probe systems. The debug is completed on our own Takaya APT1400F tester

- In Circuit Test – complete ICT solution for Teradyne systems, including on request in circuit device programming, LED tests, cluster tests, Boundary Scan and functional test sequences. For test programs debugging we have the complete range of Teradyne ICT systems.

- Flash Stations for multi-PCB panel assemblies with parallel programming, using interchangeable cassettes

- Boundary Scan – stand-alone or integrated solutions in ICT or FCT using XJTAG

- Functional Testers in various configuration, tailored to the customers needs and requirements.

We are developing the functional testers around the National Instruments software packages and using PXI or standard bench-top equipment. Together with each solution, a set of detailed documentation will be delivered. All the solutions are installed on request, at the customer site for the final fine-tunning and repeatability analysis on the production systems.

Alfa Test works with several fixture houses from Central and Eastern Europe as partners for fixture adapters manufacturing.

PCB Data Preparation

Alfa Test has the right tools and expertise to prepare your manufacturing data for your production needs.

We are able to process your Bill of Materials, CAD files, Net Lists and Schematics to be suitable with the inputs of several tens of different manufacturing, inspection and test equipments. We can process more than 40 different CAD formats.

Together with the processed data, the complete sets of reports will be provided.

Based on requests, we can export from the original data various information such as parts locations, nets, Test Points locations, GENCAD files and also input files for test equipment such as CA9 or CKT formats.

Flying Probe Test Services

We are offering board test services for small up to medium PCBA batches on our Takaya APT1400F flying probe system. The time frame between receiving the data package and the first samples tested is between several hours to several days depending on the complexity of the project.

This service include:

- test programs development and debug, starting from CAD, BOM, Schematics and samples

- boards testing, including standard MDA tests, vectorless tests, basic power on, LED color and intensity verification and optical tests for presence, polarity and OCV log files containing SN and all the measured values

- testability report

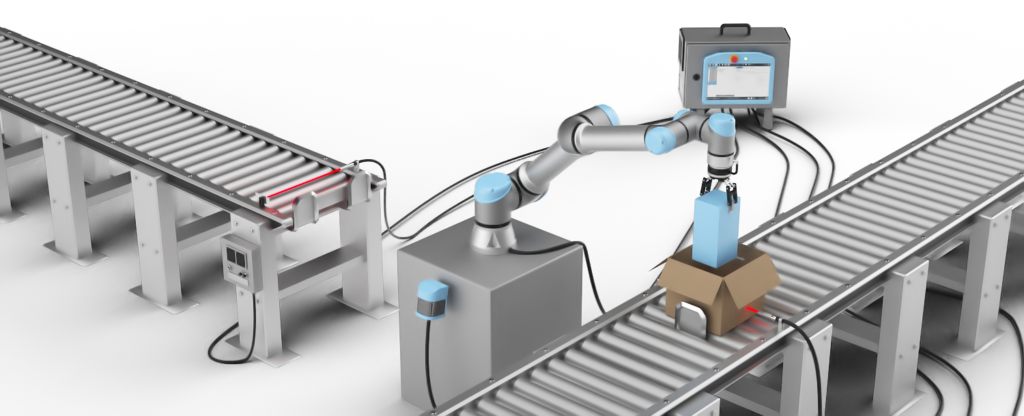

The test solutions we develop can be offered in standalone off-line configuration, in-line or as an automated test cell operated by an UR collaborative robot. The benefit of flying probe testing apart from the fast development time is the possibility to test boards that don’t have test points, by using the components pads.

X-Ray Inspection Services

In addition to the electrical test, we offer X-Ray inspection services as well, both 2D and CT, based on the customer’s specification and industry standards. The X-Ray inspection is performed on our own Waygate Technologies (former General Electric) system.

Test Strategy

By covering a wide range of expertise for Test and Inspection processes, Alfa Test is providing consultancy for the companies that want to define the right Test Strategy.

The Test Strategy of an electronic manufacturing process includes both technical and financial aspects. The goal of a specific Test Strategy is to achieve effectiveness in detecting the faults with at an affordable cost.

In defining a Test Strategy, a group of elements must be considered: from the manufacturing company characteristics, including personal skills, equipment availability and capabilities, internal standards and rules, to the product design, market segment, the end user expectation, the technologies trends and more others.

From the early phases of a project we can offer you consultancy in selecting the best Test Strategy for your products manufacturing process. We are able to run simulations (using Test Way Express) and provide you solutions to obtain the desired test and inspection coverage in the most optimum way.

By combining different scenarios of test plans , we eliminate redundant test and inspection steps without loosing effectiveness Balancing the testing and inspection times, we identify the optimum model for each test and inspection equipment. Therefore we are able to provide the right support, the documentation, the test solution and the project management, needed to select the best test strategy and the right test and inspection tools.

DFT – Design for Testability

Alfa Test has the right tools and expertise to provide you with Design For Testability analysis for your products.

Design for Testability represents a set of rules that needs to be follow when designing electronic board to get a good testability with Automatic Test Equipments. If one or more of these rules are not respected, the testability of the boards decrease, the testing effectiveness will decrease, controlling of the manufacturing processes will become more difficult, more of your bad products can be received by your customers and the list of disadvantages can continue. From the early stages of a PCB life cycle to a mature project we can check how suitable is your product for In Circuit or Boundary Scan Testing. We can also identify if any design errors might not allow performing some specific tests or tasks (as device programming) to your Unit Under Test.

These analyses are performed using Test Way, an ASTER TECHNOLOGIES advanced software. Therefore detailed analyses for different test strategies can be performed. Running various simulations will help identifying the weak points of the board design, even before the first PCB or even the CAD are ready for production and also have estimation for manufacturing yield, test processes cost, etc.

Later on, theoretical model can be compared with the real testability achieved and improvement can be implemented to cover the eventual escapes in the test development phases. Having these DFT analyses as early as possible in your design phase it is a cost saving element, as later changing the design may require a lot of changes in the entire manufacturing and test flow at a much higher cost.

Test Process Improvement

Our customers can benefit from the Alfa Test expertise in Test Engineering in order to improve their Test Processes. We are able to provide all range of support activities from phone-support to on site presence. We are able to transform your test and inspection processes from a non value add to an effective process, by placing the right tester, running the right test routines in the right location in your production flow. During workshops and training our goal is to improve your Test personnel skills for a more effectiveness usage of your Test Equipments, in order to reduce the Test time and to increase Test coverage.

By helping to identify your test process problems, you will benefit at the end from less repairs, higher manufacturing yields and fewer breakdowns of your test equipments. Having the right methods to extract the right information from your test and inspection equipments your debug/repair personnel will be able to better understand the boards defects, decrease the debug/repair loops and at the end reduce your bone-pile.

Using an ASTER TECHNOLOGIES dedicated software TestWay Express, we compare the real coverage of your test equipment with the standard theoretical model for different categories of testers (e.g. AOI, AXI, ICT, FPT, BST, etc). As a result, we are able to perform analyses on your test programs, identify the escapes and increase the efficiency.

Balancing the test steps on different test and inspection stage and eliminating the redundant test and inspection steps will result in a better utilization of your assets.

Support

For our portfolio of Test and Inspection Equipment that we are distributing, we are offering a full range of support, from on-phone to on-site support.

Our services include:

- start-up / decommissioning

- troubleshooting

- on-site full support for custom application

- hardware and software upgrades

- calibration and verification

- preventive and corrective maintenance

- troubleshooting, maintenance, operation and programming trainings

- radiation survey for the X-Ray inspection systems.

Our supported Test and Inspection Equipment are:

- Teradyne In Circuit testers

- Takaya Flying Probe testers

- Mirtec Automated Optical Inspection systems

- Waygate X-Ray Inspection systems.

Core training

Check availability here.

You must have completed the UR Academy free e-Learning Core Track before attending this training.

After the 2-day course, you will have hands-on experience with a UR robot. You will have programmed the robot several times to perform common tasks, including the operation of common peripherals (conveyors, sensors, grippers). You will be able to optimize a pick and place flow, perform palletization, understand safety concepts, and know the additional resources available to them both online and through other training courses. You will be ready to return to your own robot and create pick and place, palletization, and other common application programs on your own.

Advanced training

Check availability here.

Registration requires prior completion of In-Class Core Training.

When you complete the Advanced course, you will be able to fully understand and utilize all commands in the Universal Robots “User Interface”. You will also be able to better optimize your application and reduce the number of waypoints used by utilizing variable waypoints and user-defined features. The latter feature can assist you to align the movement of the robot to the installation or environment. Conveyor tracking and advanced force control will also be explored in this training course. This course enables every developer to deploy applications that account for more environmental variables.