Alfa Test is the regional partner for Waygate Technologies in Romania, Bulgaria, Serbia, Croatia, Slovenia, North Macedonia and Bosnia for the X-ray inspection equipment’s 2D and CT.

Waygate Technologies is a leading manufacturer of high-resolution 2D X-ray inspection and 3D computed tomography systems for non-destructive testing and 3D metrology.

Founded in 1999 in Wunstorf/Germany under the name of phoenix|X-ray, acquired in 2007 by GE Sensing & Inspection Technologies and adding a new face in 2017 and 2020, Waygate Technologies has more than 3500 equipment’s worldwide.

The phoenix Microme|x NEO 160 X-ray inspection system is designed for the special needs of the high-resolution inspection of electronic assemblies, components and PCBA. The system is equipped with an unlimited lifetime 160 kV/ 20 W microfocus X-ray tube. Due to the high energy and power of the Xray tube the phoenix Microme|x NEO 160 meets the requirements for electronic applications including power electronics. The system comes standard with the unique phoenix x|act base software solution. This software offers ease use and allows manual as well as automatic inspection.

Key features & benefits

- Unlimited lifetime 160 kV / 20 W X-ray tube to penetrate even high absorbing components

- Improved live inspection capability due to high contrast flat panel detector option

- Easy and fast computed tomography (CT) due to comprehensive software package

- Live CAD data overlay

- Automated real X-ray sample map for easy orientation on top, bottom and even inside samples

- Anti-collision feature to protect samples

The phoenix microme|x NEO 180 combines high-resolution 2D X-ray technology and computed tomography in one system. Innovative and unique features and an extreme high positioning accuracy make the system the effective and reliable solution for a wide spectrum of 2D and 3D inspection tasks: R&D, failure analysis, process and quality control as well as automated offline inspection.

Key features & benefits

- Temperature stabilized digital DXR detector with active cooling for high dynamic live imaging

- 180 kV / 20 W high-power submicron tube with up to 0.5 μm detail detectability

- x|act package for CAD based μAXI programming and automatic inspection

- diamond|window for up to 2 times faster data acquisition at the same high image quality level as a new standard

- Optionally 3D computed tomography scans within 10 seconds

The nanome|x NEO 180 is an ultra high-resolution nanofocus X-ray inspection system designed for inspecting high-quality assemblies and interconnections in the semiconductor and SMT industries. The system offers excellent performance and versatility and can be used for 2D X-ray inspection as well as for full 3D computed tomography (nano ct).

Key features & benefits

- Temperature stabilized digital DXR detector with active cooling for high dynamic live imaging

- 180 kV / 20 W high-power nanofocus tube with up to 0.2 μm detail detectability

- x|act package for CAD based μAXI programming and automatic inspection

- diamond|window for up to 2 times faster data acquisition at the same high image quality level

- Optionally 3D computed tomography scans within 10 seconds

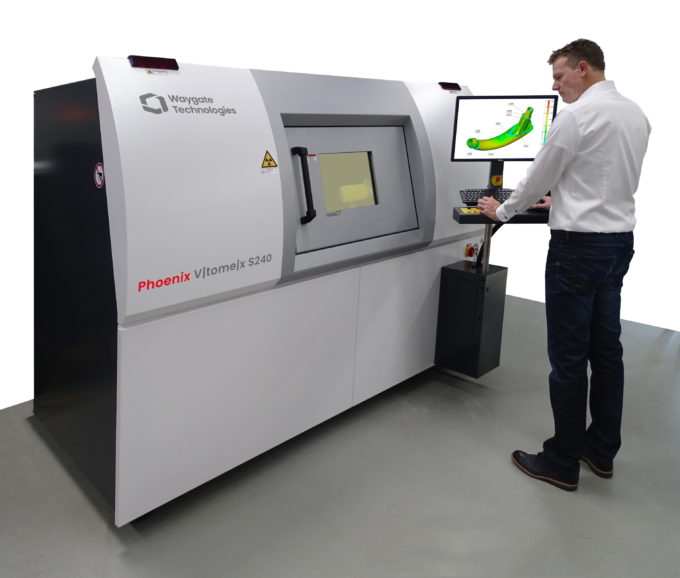

The Phoenix V|tome|x S240 is one of the few CT systems worldwide combining the highly efficient Dynamic 41 detector technology and High-flux|target – enabling high image quality as it scans much faster, or with improved accuracy, and truly revolutionizing inspection.

Whether you need to increase speed, detection detail, or do both, the Phoenix V|tome|x S240 can be formatted for any 3D industrial or scientific microCT task. To allow high flexibility, the V|tome|x S240 may optionally be equipped with both, a 180 kV/15 W high-power nanofocus X-ray tube and a 240 kV/320 W microfocus X-ray tube. Due to this unique combination, the system is an ideal tool for a wide range of applications from extreme high-resolution scans of low absorbing materials as well as for 3D analysis of high absorbing objects up to 400 mm in diameter.

The system covers a wide range of application capabilities:

- Internal defect analysis

- 3D quantitative porosity analysis

- Flexible 2D X-ray inspection

- Material structure analysis

- Assembly control

- CAD data nom/act comparison

The new Phoenix V|tome|x M pushes this innovation one step further to give you the most versatile and precise X-ray microfocus CT system for NDT and 3D metrology and analysis. This highly productive scanner delivers improved accuracy at unprecedented speeds-helping you dramatically optimize your lab processes to meet today’s increasing demands.

Whether you need to increase speed, detection detail, or do both, the Phoenix V|tome|x M can be formatted for any 3D industrial or scientific microCT task. The first CT system worldwide, this versatile high-resolution scanner works with a variety of optional features like Scatter|correct to meet your high-quality inspection needs with up to two times faster inspections or scanning volume with up to 300kV/500W—all to help you make the most out of your inspections.

Metrology 2.0:

- Nominal-actual CAD comparison

- Dimensional measurements /wall thickness analysis

- Reverse engineering / tool compensation

- (3.8 + L/100 mm) μm referring to VDI 2630 guideline.

- (5.5 + L/100 mm) μm at any other z and y position between both VDI 2630 positions

- (3.8 + L/100 mm) μm at any position after applying the easy|calib tool.

The phoenix v|tome|x L 240/300 and L 450 are versatile high resolution microfocus systems for 3D and 2D Computed Tomography and 2D non-destructive X-ray inspection. With their granite based 8-axes manipulation they are handling even large samples with highest precision. Both systems are the optimal solution for void and flaw detection and 3D metrology (e.g. first article inspection) of castings. Furthermore, phoenix|x-rays high resolution X-ray technology with many extras like an optionally second X-ray tube allows to adapt the v|tome|x L to any kind of industrial and scientific CT application. A variety of effective software tools minimizes physical effects like ring-artefacts or beam-hardenings for highest CT quality.

Key features:

- Long-life open micro- and nanofocus X-ray tubes

- Unique 300 kV / 500 W unipolar microfocus tube for high magnification

- Granite based precision manipulation up to 8 axes.

- High precision CNC control

- High dynamic temperature stabilized detector technology

- High contrast array detector + multiline detector or line detector for 2D CT

- Virtual detector enlargement

- Fully automated click & measure|CT

The Phoenix V|tome|x C450 offers compact production-oriented, high-throughput CT for at line 3D failure analysis and precision 3D metrology of large parts in the aerospace and automotive industries. It boasts a robust, small footprint for statistical production process control with a low cost of ownership and ease of use-delivering the flexibility to inspect different parts from different production lines.

The Phoenix V|tome|x C450 offers industry-leading sample size, flexibility, and maximum penetration power for high-absorbing samples at 450KV. It delivers extremely high-quality cone beam minifocusCT with the lowest possible scatter artifact level.

With new automation functionality, you can minimize operator time and influence, while highly increasing the repeatability and reproducibility of CT results. And with easy loading tools and automation features, it’s easier than ever to use.

Applications:

- Large light metal castings

- Small steel castings

- Additive manufactured parts

- Composites

Speed|scan HD handles large production batches, with up to 100% inline inspection.

Fully automated part handling and a bundle of CT innovations enable 24/7 Speed|scan HD operation at exceptional voxel resolutions down to 25 microns. With advanced artificial intelligence (A/I)- based battery anode overhang analysis as well as automatic defect recognition (ADR) for pass/fail decisions and fully automated CT workflows, the system is setting new standards for reliable and precise production control.

Inline CT with Phoenix Speed|scan HD allows a wide range of 3D evaluations:

- Internal defect analysis

- 3D quantitative porosity analysis

- Assembly control

- Materials structure analysis

- Automated defect recognition (ADR)

- CAD Data nom/act comparison

Phoenix Nanotom M – versatile 3D CT system

High-resolution computed tomography (CT) has become a powerful inspection tool for a wide range of industrial and scientific inspection and metrology applications such as non-destructive structure and failure analysis as well as for quality assurance or production control.

With its special design, the Nanotom M provides focal spot sizes in the submicron range. Smaller focal spots ensure very little geometric unsharpness and therefore improved image resolution. And due to its high dynamic range detector, the system offers long-term stability and optimized image quality.

In pursuit of potential high-resolution images with ease of use in an economy environment, nanoCT can compete in many application fields with limited available synchrotron facilities, e.g.:

- Materials science

- Micro-engineering

- Electronics

- Life sciences

- Geosciences and much more